How to Choose a Reliable Tufted Mats Manufacturer

What Is a Tufted Mat and Where Is It Used?

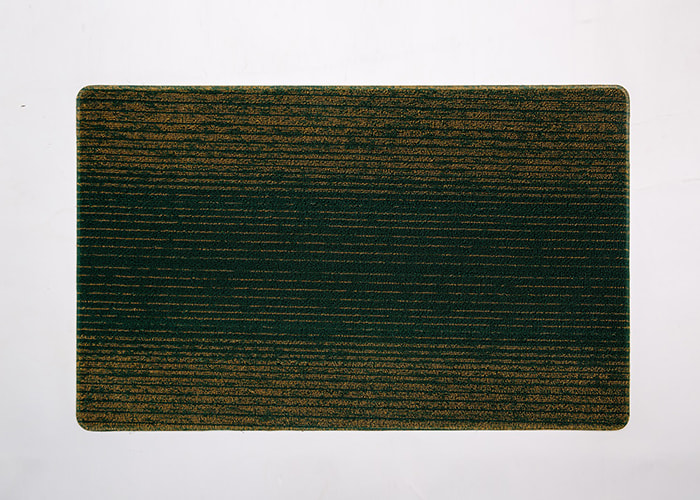

A tufted mat is a specific type of floor covering created by inserting loops of yarn through a backing material, creating a dense, textured surface. This process, similar to that used in carpet manufacturing, results in a product known for durability, high dirt and moisture absorption, and scrape-off capabilities. Unlike flat-woven or rubber mats, the tufted construction provides a deeper pile that can trap debris effectively. These mats are commonly seen at commercial building entrances, in hotel lobbies, healthcare facilities, and even in high-end residential settings. Their primary function is to manage foot-borne dirt and moisture, protecting interior floors while offering a degree of underfoot comfort. When businesses or facilities managers seek a long-lasting entrance solution, they often turn to a specialized tufted mats manufacturer to source products tailored to heavy traffic and specific aesthetic requirements.

What Key Factors Differentiate Manufacturers?

Selecting a tufted mat manufacturer involves more than comparing price lists. The quality and consistency of materials are fundamental differentiators. A reputable manufacturer will be transparent about the yarn types used, such as solution-dyed nylon for fade resistance, and the density of the tufting. The backing system is equally critical; it should provide dimensional stability to prevent curling and include a strong, non-slip secondary backing for safety. Customization capability is another major factor. A manufacturer with strong design and production flexibility can offer custom sizes, precise color matching to corporate branding, and even logo integration directly into the mat. This level of service is distinct from a supplier that only sells standard, off-the-shelf products.

Beyond the product itself, the manufacturer’s expertise and support services are vital. A knowledgeable tufted mats manufacturer acts as a consultant, advising on the mat design for specific traffic patterns, climate conditions, and cleaning protocols. They should provide clear data on mat performance, such as moisture absorption rates and durability testing results. Reliable manufacturers often offer comprehensive services, including CAD drawings for precise planning, sample programs for evaluation, and clear warranty terms that reflect confidence in their product’s longevity. The ability to handle logistical complexities, from bulk commercial orders to coordinated multi-location deliveries, also separates established manufacturers from smaller operations.

Why Are Production Capabilities and Compliance Important?

The scale and technology of a manufacturer’s production facilities directly impact product quality, times, and the ability to fulfill large orders. Inquiring about a tufted mat manufacturer’s in-house capabilities is important. Do they control the entire process from yarn spinning and dyeing to tufting and backing? Vertical integration often leads to better quality control and more consistent output. Modern, computerized tufting machines allow for intricate patterns and precise pile heights, which are signs of a technically advanced producer. For projects with tight deadlines or large square footage requirements, the manufacturer’s production capacity and inventory of raw materials become practical concerns.

Compliance with industry standards and sustainability practices is increasingly a deciding factor. A responsible tufted mats manufacturer should have their products tested for critical safety standards, such as fire resistance and slip resistance. Environmental considerations are also prominent. Many clients now seek information about the recycled content of materials, the sustainability of the yarn source, and the overall environmental footprint of the production process. Manufacturers that prioritize eco-friendly practices and can provide relevant certifications or documentation are better positioned to meet the procurement requirements of modern corporations and institutions. This focus on responsible manufacturing adds a significant layer of value and risk mitigation for the buyer.

.jpg)

.jpg)